Improve Access Efficiency: Make Inventory Management More Accurate

Rapid changes in the electronics industry require efficient warehousing

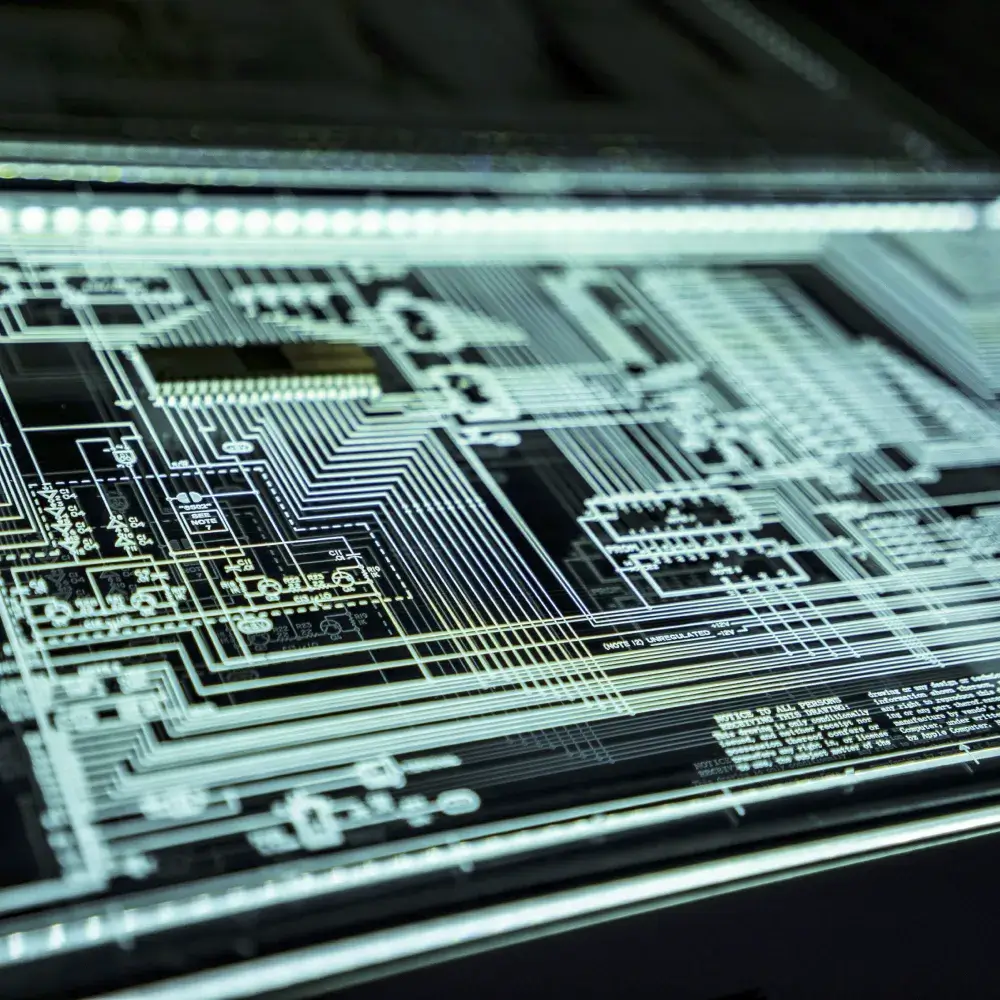

The electronics industry emphasizes fast supply chain and just-in-time production, and traditional storage methods are prone to errors and delays caused by human factors. otobro automated warehousing system can greatly improve the access efficiency and ensure that materials are supplied in real time without errors.